The brands are under continuous pressure to launch new products fast without compromising on the quality, functionality, and appearance of the new products. One of the most effective solutions to this dilemma has been rapid prototyping, which enables the development timelines to be shortened by the cosmetic brands without affecting the integrity of the design or the expectations of the consumers. Companies like UKPACK are focusing on 3F services for their customers.

Rapid Prototyping in Cosmetic Packaging

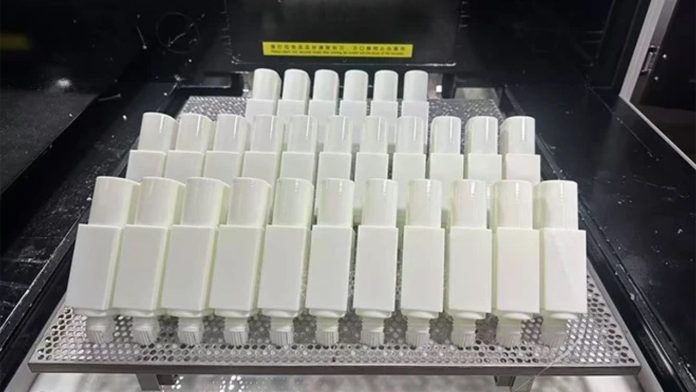

Rapid prototyping is a phenomenon of designing the packaging with high-tech technologies, including 3D printing and digital manufacturing. These prototypes can be considered as a form, dimension, and the visual form of the final packaging, allowing these teams to test designs at the early stages of development. Brands can also check the physical models within days instead of waiting until the expensive molds or time-consuming production samples are finished.

Rapid prototyping can be used in the development of cosmetic packaging to fill the digital-to-mass production gap. It offers a feasible method of testing the visual concepts, fine-tuning of proportions, and alignment of the stakeholders in an effort to place a bet on actual manufacturing.

Speeding up Decision-Making

Among the greatest benefits of rapid prototyping, the effect on the speed of making a decision can be mentioned. Once the teams have the ability to touch and look at a prototype, the discussions will be more fruitful and effective. Marketers, product managers, and designers are able to review the same item, minimizing misunderstandings and subjectivity.

The timely availability of physical models enables brands to give the green light to the designs sooner or seek modifications instantly. This removes the time wasting of back-and-forth revisions and reduces the length of the total development cycle. The ability to clear design issues early will enable the cosmetic brands to proceed to production without any hitches.

Minimization of Design Revisions

The development of traditional packaging usually consists of several cycles of changes when the tooling or sample production has started, which increases the cost and time schedule. Rapid prototyping will reduce these risks because possible problems will be revealed at the initial stages. Design issues, the lack of proportions, or branding issues can be identified and eliminated before turning into expensive solutions.

This proactive solution will greatly minimize the chances of late-stage amendments. This makes the process of development more predictable and efficient, and makes the brands avoid unforeseen delays, which may delay a product launch.

Enhancing Teamwork between Teams

Close coordination between the design, marketing, engineering, and manufacturing teams is needed when it comes to launching cosmetic products. Rapid prototyping also facilitates this cooperation through the fact that it gives a common reference point that everybody can assess. Physical prototype conveys design intent more efficiently than computer files alone, and all stakeholders get the same message.

This alignment makes the approvals faster and enhances communication with the external partners, such as the manufacturers or suppliers. Under the circumstances that expectations are made early on, the design-to-production process is made easier and quicker.

Improving Competitive Advantage and Market Readiness

Speed to market is a vital element in the cosmetics business, whereby trends change at a very fast rate, and consumer preferences also change very fast. Rapid prototyping enables brands to react to these changes in a bright manner. Shorter development cycles allow brands to launch new products when the trends have not become old and have a higher chance of commercial success.

Competitive advantage is also offered in faster launches. The brands that continuously introduce a product to the market faster have a better chance to attract the attention of consumers and become their innovators. Rapid prototyping helps this agility without compromising quality and brand consistency.

Justifying Confident Investment Decisions

Brands should be assured that their packaging design is achieving aesthetic as well as a strategic objective before they make a commitment to mass production. This confidence is founded on rapid prototypes. Viewing and touching a physical model allows the decision-makers to assess the suitability of the packaging with brand positioning and consumer expectations.

Such transparency eliminates indecision and accelerates the decision-making process. Having more confidence in its decisions regarding the design, the brand will be able to go into production faster and with fewer internal hindrances.

Facilitating Scalable and Effective Manufacturing

The rapid prototyping is also significant in making ready the designs for scalable manufacturing. Discussing the perfection of designs in the initial stages, brands have a chance to make sure that the company will produce a more appropriate version. Possible manufacturing difficulties may be detected and solved before the tooling is commenced, which will be of great importance in the process later.

Conclusion

Rapid prototyping has proven to be a highly important tool in the accelerated launch of cosmetic products in a market that is increasingly becoming competitive. It can make the way between the deal and the shelf much shorter as it enables making decisions faster, reducing the risks of the development, cooperating more, and getting ready for the market better. Rapid prototyping offers a business idea to the cosmetic industries that wish to follow the latest trends and meet the demands of the customers. It makes speed become a sustainable strength without costing in terms of brand and quality through early validation and successful development.