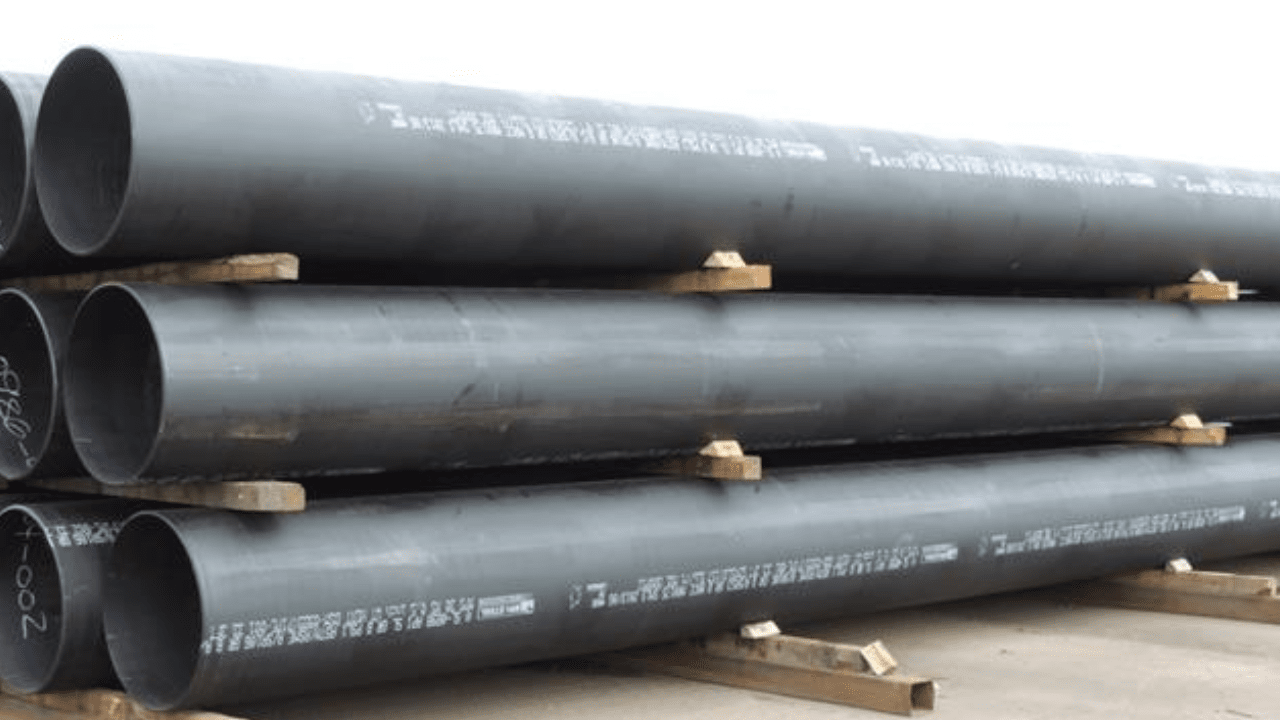

What are the ASTM A252 Required Material Properties and Production Techniques?

Important hints for the material homes and assembly techniques required for the development of large steel pipe piles are outlined in ASTM A252. These requirements make certain principal uprightness and execution in a variety of building programs. They consist of traumatic determinations for electricity, compound introduction, and effect competition.

Constant and reliable advent tactics, including steel and line-producing strategies, are illustrated. Following the astm a252 guidelines is vital to preserving safety and excellent requirements on a construction basis. This industry-leading fashion specifies the importance of fabric residences and assembly methods.

Substances with Mandatory ASTM A252 Properties

The subsequent are the fabric features required with the aid of ASTM A252:

Energy Level Requirements

To guarantee their structural integrity and dependability, ASTM A252 steel pipe piles have to meet strict strength requirements. The minimum yield of electricity and minimum tensile power are the 2 main focuses of those standards.

Tensile energy

The minimal tensile electricity standards for the metal used in the production of seamless and welded metal pipe piles are distinctive by using ASTM A252. This function, which determines the highest stress a cloth can preserve before failing under pressure, is vital for making certain the piles’ structural soundness and potential to guide loads.

Yield Strength

Another important material attribute required with the aid of ASTM A252 is yield energy. It stands for the best pressure that a cloth can face up to before permanently deforming or yielding. It’s far ensured that the steel used in pipe piles can maintain applied hundreds and retain structural balance without present process plastic deformation through the assembly of the prescribed minimum yield strength.

Elongation

Metals used in pipe piles must meet minimum elongation needs specific with the aid of ASTM A252. Elongation is an asset of substances that exhibits their ductility and capacity to flex without breaking for the duration of a tensile taken a look at. Its thousands are measured as the share boom in duration before fracture.

Enough elongation guarantees that the metal can face up to deformation and harden concentrated areas of stress without breaking down.

Impact Toughness

The potential of a fabric to withstand fracture and take in energy in the event of abrupt loading situations, such as impact or surprise, is measured through effect sturdiness. The minimal requirements for the Charpy V-notch effect trying out, which is used to assess the toughness of the metallic used in pipe piling, are outlined in ASTM A252.

Production Strategies Required for ASTM A252

The following is a discussion of the manufacturing tactics required using ASTM A252:

Metallic Production

The steelmaking techniques aimed at producing first-rate metallic with the specified mechanical features and fabric composition are the first step in the ASTM A252 meeting of metal pipe thousands. Metallic may be provided with the use of diffusion techniques, inclusive of an electric round segment heater and a vital oxygen heater.

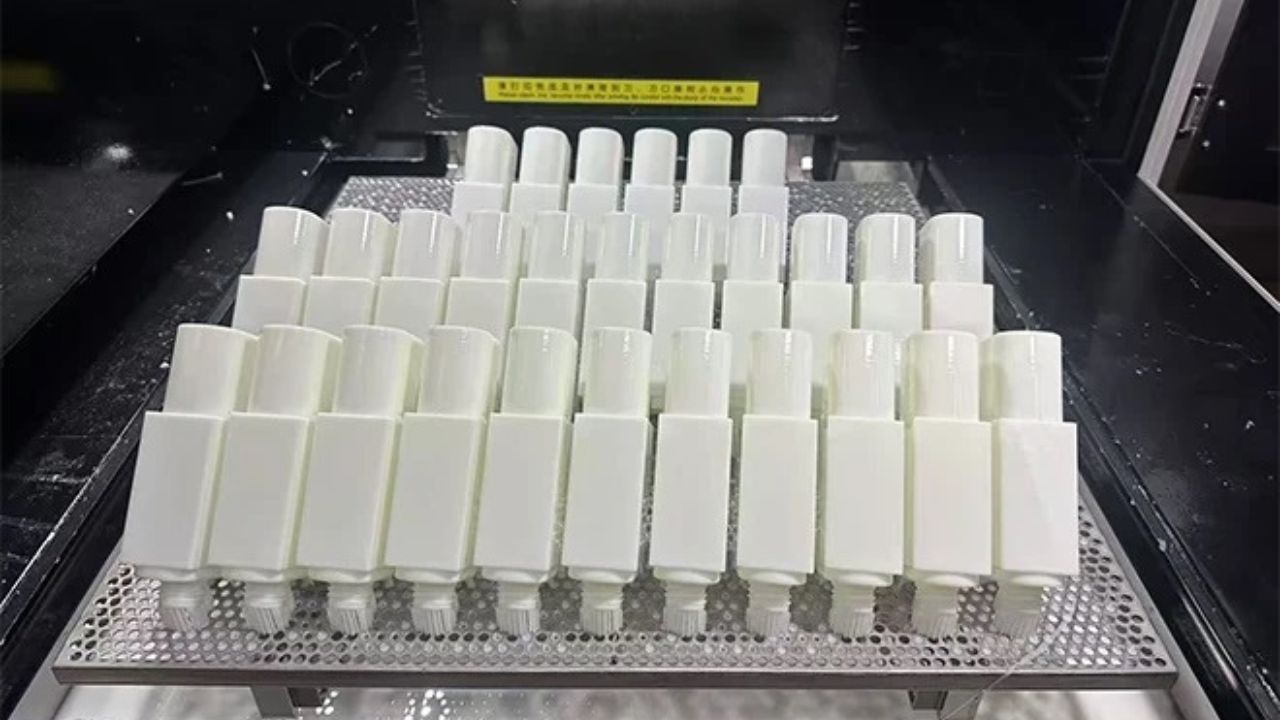

Production of Pipes

Following shipping, the metallic is placed via custom-in-shape pipe fabrication techniques to satisfy ASTM A252 necessities for layering accuracy, weldability, and underlying respectability. The formation of each uniform and welded steel pipe pile is allowed with the aid of ASTM A252.

Testing and First-class Assurance

As part of the ASTM A252 meeting procedures, pleasant management and trying out are important to ensure the reliability and performance of metallic pipe piles. To pick out defects, discontinuities, and blemishes within the cloth and welds, manufacturers use a diffusion of NDT techniques, which include radiographic checking out (RT), appealing molecule examination (MPI), and ultrasonic testing (UT).

Metal pipe piles have to undergo mechanical checking out according to ASTM A252 for you to evaluate their durability, pliability, and unity. In the course of the meeting system, visible and layered inspections are carried out to ensure adherence to ASTM A252 specs for floor completeness, elements, straightness, and resistances.

Concluding Remarks

ASTM A252 specifies stiff cloth characteristics and meeting approaches for metallic pipe piles. Following those recommendations ensures that the given thousands meet the requirements of numerous improvement and framework tasks with reliability and best affirmation. They also ensure that the thousands have the predicted electricity, Compound Corporation, and primary respectability.