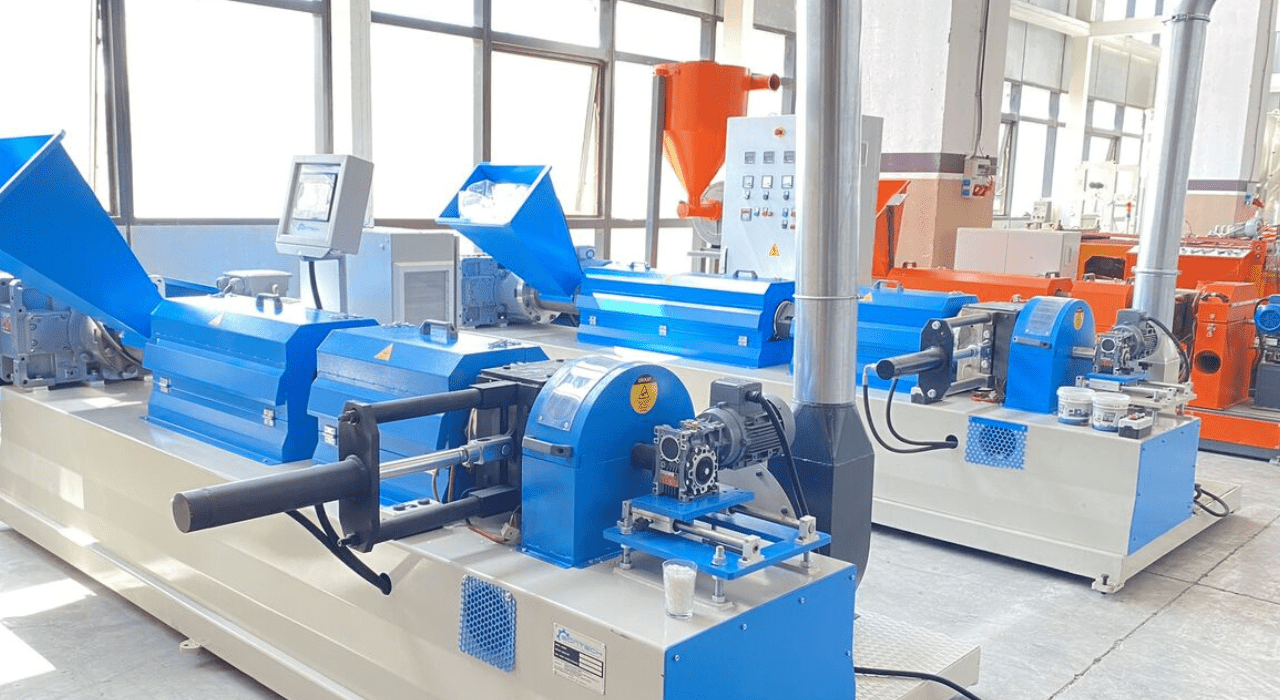

Which substances can be processed by Plastic Crushing Machines?

Plastic crushing machines are critical equipment in the plastic reusing enterprise, playing a crucial part in the initial recycling arrangement via breaking down plastic squander into smaller, possible pieces. These machines are designed to handle many plastic substances, making them flexible and effective. They can process common plastics such as those utilized in bottles, found in nourishment containers and straws, and used in things like drain containers and plastic packs.

Furthermore, plastic crusher machine can handle harder materials like PVC, which is utilized in pipes and cable insulation. By decreasing plastic waste into smaller particles, these machines encourage less demanding washing, dissolving, and remolding forms, eventually contributing to the creation of high-quality reused plastic items.

Plastic Crushing Machines Process Material

Understanding which materials can be processed by plastic crushing machines is basic for optimizing their utilization and maximizing the reusing preparation. This information guarantees proficient handling of different plastics, upgrading the generally reusing workflow, and contributing to the generation of high-quality recycled materials.

PET

Polyethylene Terephthalate is a common form of plastic utilized basically for packaging, which includes plastic bottles for water and delicate liquids. Pet is relatively recyclable and, while organized through a plastic crusher, it may be modified into little chips or pellets. these can then be washed, liquefied, and remolded into modern pet items.

PP

Polypropylene (PP) is some other widely applied plastic, discovered in such things as bottle caps, straws, and food bins. It is recognized for its durability and resistance to extraordinary chemical solvents, acids, and bases. Plastic crushing machines can efficiently damage down PP materials into little particles, making them simpler to smooth and manner in consequent reusing levels.

PE

Polyethylene (PE) is one of the maximum commonplace plastics, available in two crucial shapes: high-density Polyethylene (HDPE) and low-density. Polyethylene. HDPE is utilized in items like drain containers, cleanser bottles, and piping, whereas LDPE is found in plastic packs, films, and squeeze bottles. Both HDPE and LDPE can be handled by plastic crushers. The machines break down these plastics into drops, which can then be washed and reused into unused items, such as plastic stumble, channeling, and holders.

PVC

Polyvinyl Chloride (PVC) is utilized in a wide extend of applications, including counting channels, cable separators, and vinyl flooring. PVC could be a solid plastic but can be challenging to reuse due to the added substances it contains. Be that as it may, plastic crushing machines are capable of handling PVC materials, reducing them to reasonable pieces.

EVA

Ethylene Vinyl Acetate (EVA) is a plastic utilized in froth items, shoe soles, and as a sealant in bundling. EVA’s adaptability and versatility make it a well-known fabric, but it moreover requires specialized handling amid reusing. Plastic crushers can handle EVA, breaking it down into little particles that can be cleaned and reused. Reused EVA is regularly utilized within the generation of modern froth items, footwear, and sports hardware.

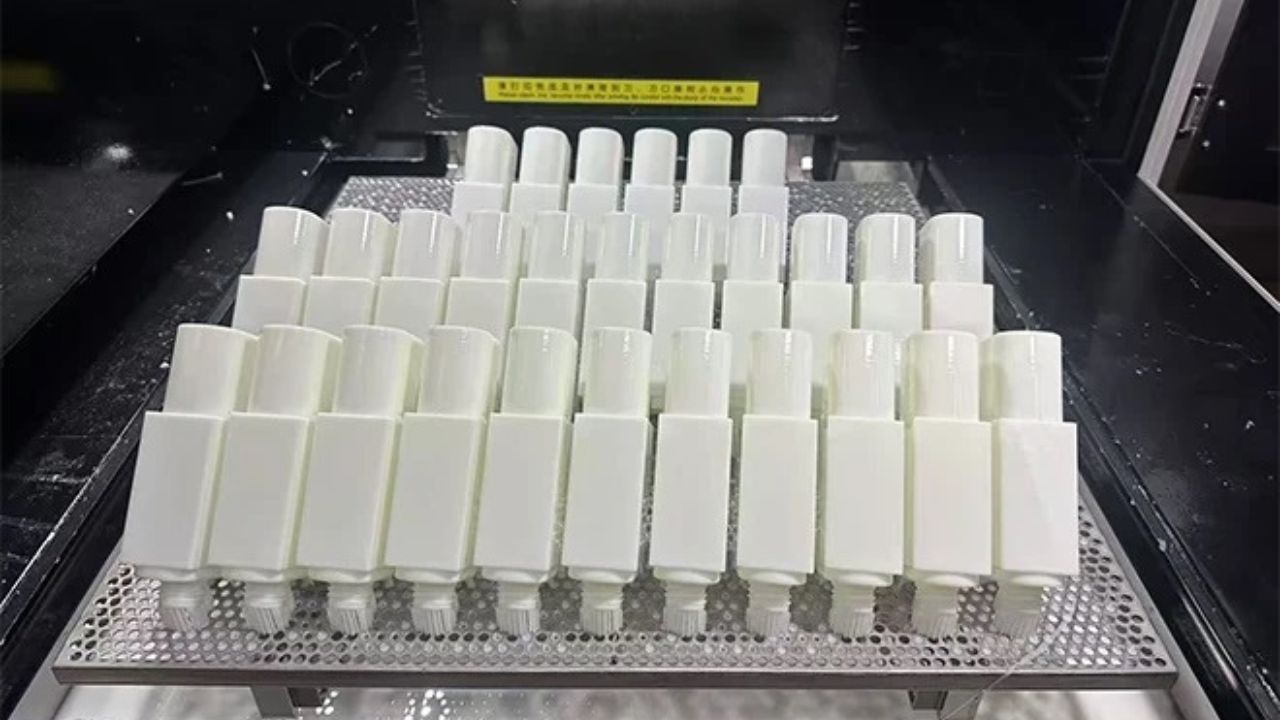

Plastic Bottles and containers

Plastic bottles and containers, crafted from numerous sorts of plastics like pet, HDPE, and PP, are the various most commonplace things organized through plastic crushing machines.

These machines can effectively diminish the measure of bottles and holders, making them simpler to wash and handle in advance. The resulting drops or pellets can be reused into new bottles, holders, and other plastic items, advancing a circular economy.

Plastic Film and Bags

Plastic films and packs, regularly made from LDPE, display unique challenges due to their lightweight and flexible nature. Plastic crushing machines are planned to handle these materials by destroying them into smaller pieces. This makes it less demanding to evacuate contaminants amid the washing prepare and plan the fabric for reusing. Reused plastic film and packs can be utilized to deliver unused bundling materials, trash packs, and development films.

Woven Bags

Woven plastic bags, regularly crafted from PP, are applied for carrying foodstuffs, grains, and other bulk things. These bags can be processed through plastic crushers, which damage them down into smaller portions that may be cleaned and recycled. The reused material from woven sacks can be utilized to create contemporary sacks, mats, and different difficult plastic items.

Plastic Profiles, Pipes, Sheets, and Sheets

Plastic profiles, channels, boards, and sheets, crafted from one-of-a-kind styles of plastics such as percent and HDPE, are common in construction and fabricating. Plastic smashing machines can process these materials, reducing them to pieces or pellets. This permits simpler washing and encourages the reusing of modern items, such as development materials, furniture, and plastic sheets.

Plastic Shells

Plastic shells, consisting of the ones applied in electronics, machines, and automobile parts, can moreover be processed through plastic crushing machines. These shells are regularly made from difficult plastics like ABS (Acrylonitrile Butadiene Styrene) and HIPS (high-impact polystyrene). The machines damage the shells into smaller pieces, which can then be cleaned and reused into new items.

Conclusion

Plastic crushing machines are versatile and essential devices in the plastic recycling industry, competent in handling a wide extend of materials including PET, PP, PE, PVC, EVA, and more. By effectively breaking down plastic squander into smaller, reasonable pieces, these machines encourage the reusing process, making a difference in decreasing environmental effects and advancing maintainability.