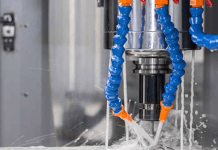

It can be a common and disruptive problem in industrial settings when compressor variable speed drive produces excessive noise. Controlling this noise becomes essential for complying to noise rules, protecting public health, and providing workers with a more comfortable working environment. Effective mitigation measures and a thorough understanding of the main causes are needed to address this issue. This article will look at a number of methods and useful advice for reducing excessive noise in compressor variable speed drives. Businesses can reduce noise levels, improve operational efficiency, and maintain a safer and more effective workspace by putting these steps into place.

Tips For Controlling Excess Noise In Compressors

- To restrict and reduce noise levels surrounding the air compressor, install soundproof cabinets or enclosures.

- Insulate the compressor room’s walls, ceiling, and floor with noise-canceling materials like acoustic foam or insulation panels.

- Make sure the compressor room has adequate ventilation to minimize overheating and for air circulation, which can help lower noise levels.

- To separate the compressor from the floor or mounting surface and reduce vibration transfer, use anti-vibration mounts or pads. This also reduces noise.

- By lubricating moving parts, cleaning and replacing air filters, and attending to any problems as soon as they arise, keep the compressor in good working order.

- To help reduce noise during operation, attach noise-reducing devices to the compressor’s air intake and exhaust ports, such as silencers or mufflers.

- To reduce noise and provide a quieter environment, use sound barriers or acoustic drapes around the compressor area.

- Check the compressor and its parts frequently for any signs of wear or damage that could increase noise.

Compressor Maintenance Tips For Long-lasting Product

- Check the compressor and its connections often for any indications of air leaks.

- Leaks cause the compressor to work harder in addition to wasting energy. Any leaks should be fixed right once to stop additional harm.

- Regularly check the oil levels in the compressor to make sure they are within the prescribed range.

- Maintain regular cleanings of the compressor and its parts to get rid of dust, dirt, and oil accumulation.

- To clean delicate electrical components, use a wet cloth or a mild cleaning agent instead of spritzing them with water.

- It’s essential to get advice and assistance from a qualified technician or the manufacturer if you have questions about any maintenance activities or discover serious problems with the compressor.

Advantages Of Well-maintained Compressors

Enhanced Performance

Compressors that have been properly maintained work consistently and dependably, increasing production and productivity. Maintenance procedures guarantee that the compressor will consistently be able to fulfill the necessary air pressure and flow needs by maintaining it in top condition. This enables the compressor-powered pneumatic tools, machinery, and other equipment to perform at their peak capacities.

Greater Efficiency

Compressors that have received proper maintenance perform at their best, increasing energy efficiency. The compressor operates efficiently and smoothly when routine maintenance procedures including cleaning air filters, checking for and fixing leaks, and checking oil levels are performed.

Conclusion

Compressor variable speed drives must be kept under control to create a secure and comfortable working environment while adhering to noise restrictions. Compressors that are properly maintained increase output while also improving performance and efficiency. Visit Wemano, a reputable supplier in the sector, for knowledgeable help and a wide selection of maintenance services.